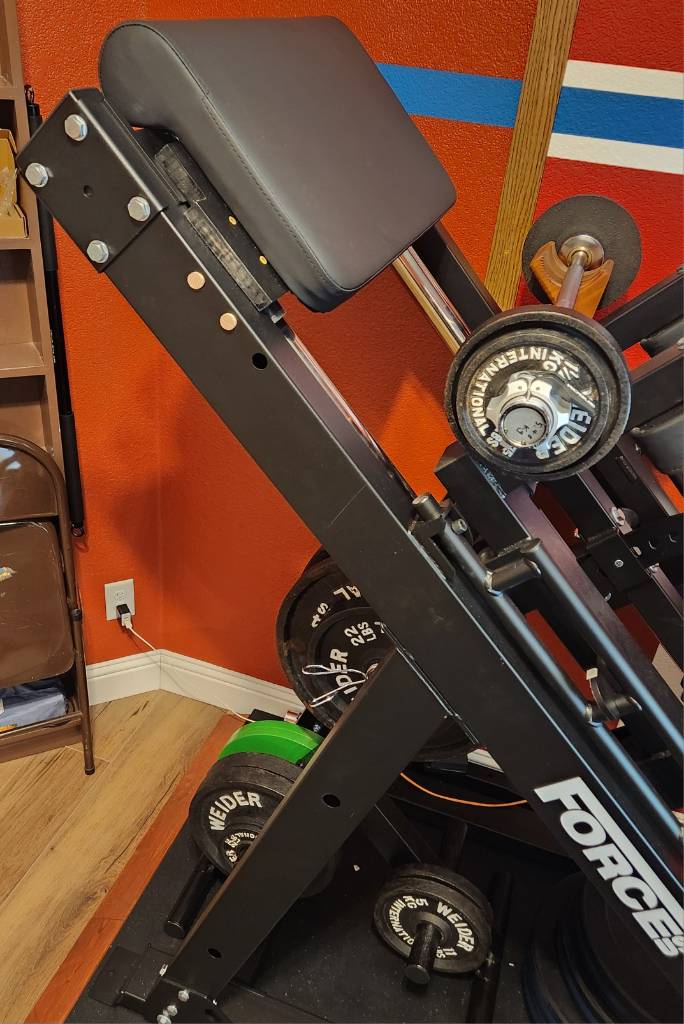

The idea for this strange combination of arm day and leg day came from realizing that my existing leg press and many commercial preacher curl benches both share a 45 degree angle. So in the interest of consolidating floor space, I decided to build a preacher curl bench attachment for my Force USA machine.

Just like with stripping down the machine to fit against a wall, the goal is to build something which is removable, if I wanted to restore the machine back to factory condition. Conveniently, at the top end of the machine, there are three 11/16 inch (17 mm) holes on each side, meant for resistance band pegs. Likewise, between the frame and the chrome running surface is approximately 1.5" (38 mm).

Thus, it made the most sense to cut pieces of 2x4 lumber (actual size: 1.5x3.5 inch) that will sit within the frame, secured by two snug-fitting 5/8 inch (16 mm) wood dowels going through the top-most band peg holes. These side-pieces are held captive by the dowels, although the pieces can still slide inward of the frame, falling away from the peg holes. They’re also not really weight-bearing. But they do provide a foundation to build upon.

To form a sturdy and flat base, I then cut some scrap 3/4 inch (19 mm) board that spans the width of the frame, and screwed it down onto the side-pieces using Torx deck screws, notched to avoid protrusions on the frame’s top surface. This makes the board weight-bearing, since it rests flat upon the frame; the side-pieces prevent the board from sliding down. And by fixing the width of the side-pieces, the pieces can no longer fall away from the peg holes.

Finally, any preacher curl bench requires a pad. For this, I simply went online and found what existing machines used. Having had a good experience with the parts department at Body Solid for my functional trainer, I looked at their GPCA1 preacher curl station, whose detailed PDF schematics showed a pad that is 600 mm wide, which is perfect for my use!

After $40 + $20 shipping, the pad arrived and I was able to measure the exact distance between its two bottom mounting holes to drill through the board. Once again, Body Solid’s documentation described the exact 5/16" wide, 1" long bolts that I would need to mount the pad.

The final result isn’t my nicest wood project – to the point that I just stained it (badly) in black – but it may have been one of the cheapest so far, using nearly entirely scrap materials except for the pad itself and the bolts. It also wasn’t terribly complex and didn’t require fairly high precision, unlike the short barbell project.

The whole premise of this attachment is that as an average height American (5 ft 9 inch; 175 cm), my range of motion for the leg press and hack squat simply won’t ever push the carriage into the upper part of the frame. So it’s free real estate.

But wait: how am I going to use this? The pad is 5.5 ft (167 cm) above the floor. I’d have to be over 7 ft tall (2.2 m) to drape my arms over it. The answer to that will be its own future post.