- cross-posted to:

- beginner_woodworking@lemmy.ml

- diy@lemmy.ml

- cross-posted to:

- beginner_woodworking@lemmy.ml

- diy@lemmy.ml

I’m not sure where the right place to post this would be, but here goes.

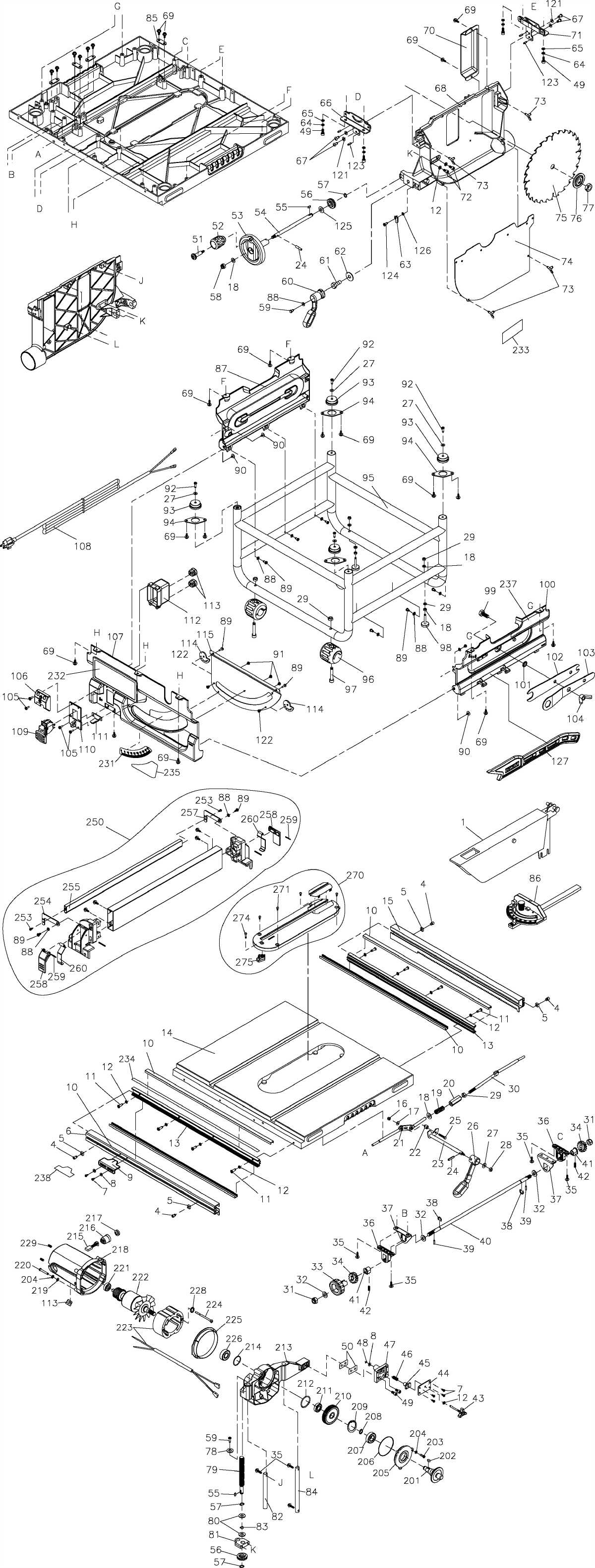

I bought this DW745 Type 2 saw off of Facebook Marketplace. I think it was abused. I replaced both of the elevating shafts (5140100-04 Diagram # 82 & 5140100-05 Diagram # 84). I also had to replace both of the bevel gears (5140061-65 Diagram # 56).

The aluminum housing seems to be okay and the lifting shafts move in and out without much resistance. I’m still getting this chunky movement when I raise and lower the blade.

I’m looking for advice before I go though the whole process of replacing the entire aluminum housing (Gear Case A25607 Diagram # 213) on the motor.

Yeah that saw has been abused.

No, it should run up and down smoothly.

First thing I would do is remove the bevel gear on the crank wheel side and turn the jack screw side by hand, testing to make sure the saw assembly runs up and down smoothly.

Mostly though I suspect the bevel gears. What I’m seeing looks like they’re meshed incorrectly/too tightly. Try any adjustment to move them relative to each other, ie back them away from each other slightly. I can’t tell if the shaft bosses have any adjustment or ability to loosen them; if they do I would loosen them slightly, turn the handle to see if the gears find somewhere they like, and then tighten it back down. Looks like it’s a simple cast assembly though.

You may be right about the tightness. I noticed that the spinning gets smoother when the saw is on it’s side as seen here in the second video I made. https://youtu.be/MdXE7IPnA6s?si=AteFwlZ1x2kFfOVt

Yeah that’s almost certainly the gear mesh.

There’s a boss that supports the jack screw near the gear end, is there any way to loosen and adjust it?

I’m attempting to learn what a shaft boss is so I can find it. Is there a part number on this exploded diagram that you can refer to?

It may be in the 30s or 50s (if that helps you find it)

A shaft boss is the bracket that holds the shaft in place; the hole that the shaft passes through. Like look at #81 in the top diagram there.

Awesome… Thanks. I know exactly what part you are talking about.

Block 5140032-73

yeah you might want to slightly loosen that amd see if it’ll shift a bit to let the gears mesh more comfy.

Well, the screws were definitely over torqued, but it didn’t fix the issue. I tried multiple methods to get one of the screws out but had to use a grinder and a flathead screwdriver to get it out.

I think I may have an Idea what is causing the issue after looking at the gears after your advice.

Since the clanky movement really only happens in one direction when the saw is on its side I figured it had something to do with the direction of the pressure being applied by the screw mechanism.

When I put the table saw completely upside down and then tried to move the blade up and down it was very smooth.

This led me to think that there might be some movement in the gears based on the pressure that’s being applied. Watch this video to see what I’m talking about and you’ll see a gap that closes when I go in one direction and opens back up in the other.

You can see the movement of the gear at about the 1:04 mark in the video.

https://youtu.be/4J7jqrm9Sn4?si=UAGNhSC3HjRo7LS8

Any advice?

I’m looking at this part of the diagram

I’m noticing part 83 (Washer 5140032-75)

That washer appears to be bent on purpose on the linked website for replacement parts and I’m guessing that it would keep the tension on the threaded dowel consistent. I think mine is missing or it was flattened out when someone torqued the mechanism.

Upon further research that is a bowed washer, spring washer, curved washer or wave washer. Their purpose is to retain tension and it’s likely the solution to my gears binding. More can be explained in this video: https://youtu.be/sG1gSQGZQl8?si=nQhzR2a8TZUwJ5rY

That’s another guess.

Would like to get some guidance here.