I am somewhat new to 3d printing and i am playing around with different filaments and print plates on my cheap ender3 v3 se.

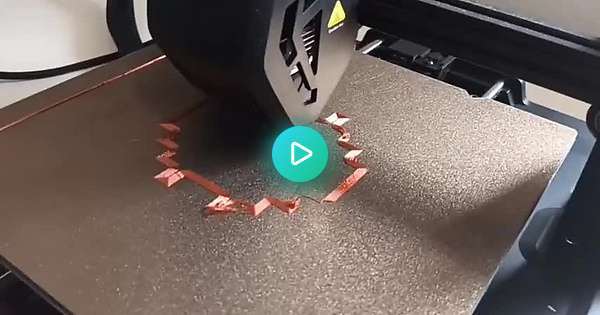

Right now I am observing a weird adhesion-issue i have not seen before: The copper-silk filament has trouble sticking to the printplate, but only in some places of the plate.

My guess it’s either some dirt/oil on the printplate. Or maybe the silk-pla has bad adhesion.

What do you think?

This printplate is this (but glued over the original printplate): https://www.amazon.de/dp/B0CL5FYHBR

The filament is this: https://www.amazon.de/dp/B09CPBRQXS

some clarification for the video: all corners of the first layer should have been rectangular. Instead some corner lost adhesion and become roundish. Here is the view from the slicer: https://imgur.com/rwA0fQW

It looks like the extrusion lines could be smushed down a bit further onto the build plate, can you set your z-offest downwards a bit so that the lines merge together more?

I like that idea. I haven’t even thought in that direction.

By how much should I change the offset? The print in the video has 0.2mm layerheight. But the worst results (i.e. total print failur) happened with 0.1mm.