it seems a very niche use case, The algo is not sub-optimal, It’s just not meant to be watertight, and trying to make the infill water tight would likely detract from what it Is meant to do.

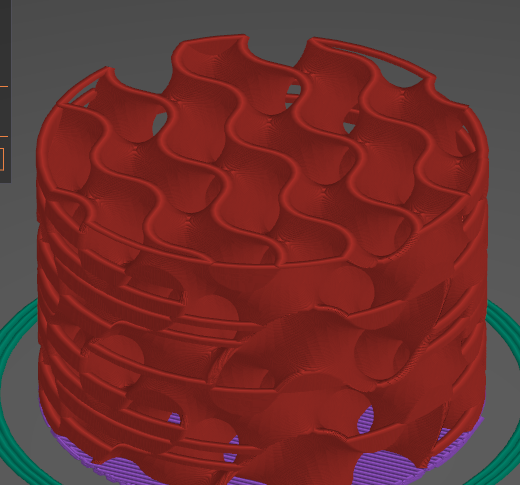

namely provide support for printing layers above it and increasing structural strength. That said, I’ve been puttering in prusa with gyriod, and it appears to create a sealed surface by going to 1mm extrusion widths, and .1mm layer heights at 25% infill. .2mm @ 30% infil also appears to be fine (but there’s small gaps where it seems to anchor.)

As far as handling overhangs better, part of the problem with going too thin on layers and overhands is there’s less material and it gets flimsy for the first few layers. you can easily extrude at 1mm widths with a .4mm nozzle without it looking too hideous.

this actually gives me an idea for a lamp shade, heh. Imagine, if you will, neopixels running in each section at the base.

Lemmy gold award for exhaustive comment

I don’t think so. It gives the opportunity to fill the printed object with resin.

You could still fill a watertight gyroid lattice with resin, if both volumes are accessible.

Though the defects are probably useful for releasing air bubbles.

This is an interesting suggestion. The unsupported overhangs at the transitions are part of why I don’t like using gyroid infill; I don’t need my infill to introduce new potential problems in a print. That said, reducing layer height would be disappointing in most cases because I also don’t need my infill to slow the print down (and with some filaments, it’s also pretty visible), so the other suggestions might be more difficult-but better-ideas. It’d be cool to try a patch someone submits.

Gyroid seems to cause more machine movement, and thus wear than other similar fills. I tend to default to cubic or cubic subdivided.

I might try gyroid again with resin fill. That’s an interesting use case.